Reactive hot melt adhesive is a solid fusible polymer, which does not contain solvent and 100% water.

It is a solid at room temperature. When heated to a certain temperature, it becomes a liquid that can flow and has a certain viscosity.

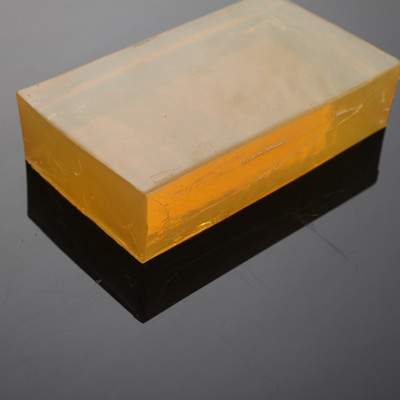

The melted hot melt adhesive is light brown or light yellow. Hot melt adhesive is composed of basic resin, tackifier, viscosity regulator and antioxidant.

Characteristic

Reactive hot melt adhesive is not as strict as other adhesives in the surface treatment of the object to be followed.

But the dust and oil stain on the surface of the object to be followed should also be properly treated in order to better play the bonding role.

Fast operation is a major feature of hot melt adhesive. The operation time of hot melt adhesive is generally about 15 seconds.

Hot melt adhesive is sensitive to temperature. When the temperature reaches a certain level, the hot melt adhesive begins to soften.

If it is lower than a certain temperature, the hot melt adhesive will become brittle.

Therefore, the temperature change of the environment where the product is located must be fully considered in the selection of hot melt adhesive.

Application

Reactive hot melt adhesive is widely used in cosmetic packaging industry (cosmetic cover, lipstick / eyelash tube, perfume bottle cap, wine bottle cap, wet towel cover).

Medical industry (plaster, surgical clothing, protective clothing, foot patch, band aid, steam eye mask, medical consumables);

Automobile industry (battery, automobile interior decoration, automobile foot pad), etc.