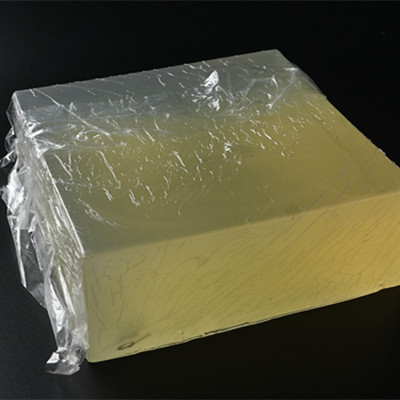

Hot melt pressure sensitive adhesive can be used to bond light thermoplastic parts.

The advantage of this adhesive is to provide fast viscosity and high treatment strength, so as to speed up the production speed.

The adhesive combines high heat resistance, relatively high strength and low creep.

These products can bring benefits to manufacturers, who can use heavy-duty bonding in exchange for faster production speed.