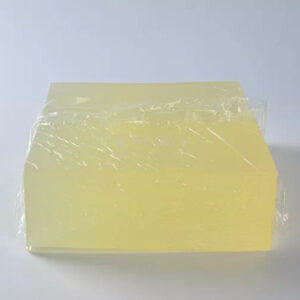

HMPSA for medical treatment has both hot-melt and pressure-sensitive properties. In the process of making rubber products, it is necessary to heat and melt through special equipment, which reflects the hot fusibility.

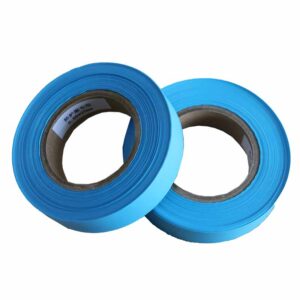

The adhesive products such as medical adhesive tape and wound patch can be bonded by finger pressure after tearing, which reflects the pressure sensitivity.