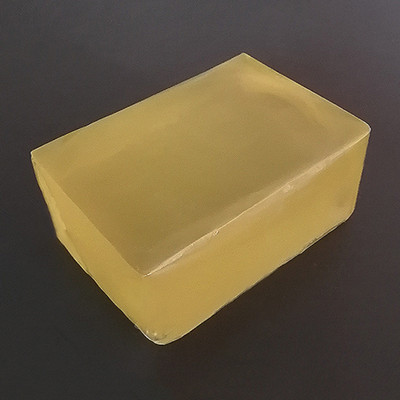

Hot melt pressure sensitive adhesive is a kind of plastic adhesive. Its physical state changes with the change of temperature within a certain temperature range, while its chemical properties remain unchanged.

It is composed of matrix resin + tackifier + plasticizer + antioxidant + filler. After melting, it becomes a liquid;

Through the hot melt hose and hot melt gun of the hot melt adhesive machine, it is sent to the surface of the bonded object, and the bonding is completed after cooling.